Aviation

Bombardier CSeries (A220)

Fly-by-wire flight controls replace the conventional hydro-mechanical flight control system. TTTECH provides an integrated communication solution based on TTP (Time-Triggered Protocol) for Parker's new generic fly-by-wire actuation platforms. This platform has been applied to the Bombardier CSeries (now A220) and Embraer Legacy 450/500 aircraft programs.

Boeing 787 Dreamliner

The 'Dreamliner’ is a successful commercial aircraft, which was developed by an international team of leading aerospace companies.

Collins Aerospace delivers electric and environmental control systems and chose TTTECH Aerospace for the development of a highly efficient TTP-based data communication platform.

Honeywell MAC

Honeywell’s Modular Aerospace Control (MAC) is a platform that permits cost-effective development of aerospace control systems. It will be employed in auxiliary power unit controls, engine monitors, integrated utility systems, distributed controls, and multi-function Full Authority Digital Engine (FADEC) controls. The high-speed data bus TTP, with readily available commercial off-the-shelf chips and tools, makes MAC highly supportable.

Space

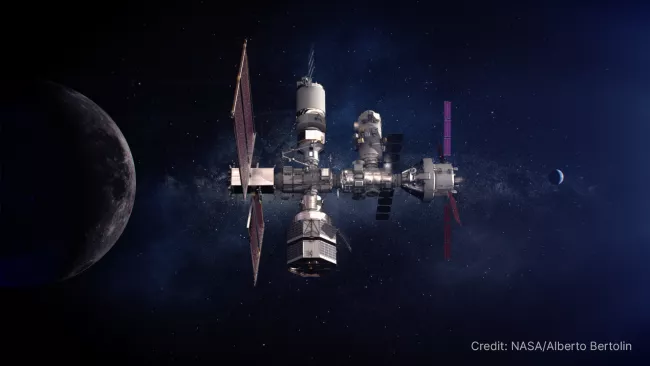

NASA's Lunar Gateway

This modular outpost in lunar orbit will serve as a way station for astronauts on their way to the Moon and, in future, for other deep space missions and is a part of the international NASA Artemis program.

TTEthernet® is used as the Gateway’s backbone network. TTTECH Aerospace and Beyond Gravity Austria have joined forces and developed a space-grade avionics platform, which is being qualified for the Gateway.

European launcher Ariane 6

The Ariane 6 launch vehicle ensures independent access to space for Europe. TTTECH Aerospace contributed substantially to the creation of the avionics backbone system in Ariane 6. Its ASICs and the related software are integrated into more than 50 avionic units, which all connect to a single, redundant TTEthernet® network, the launcher’s ‘nervous system’.

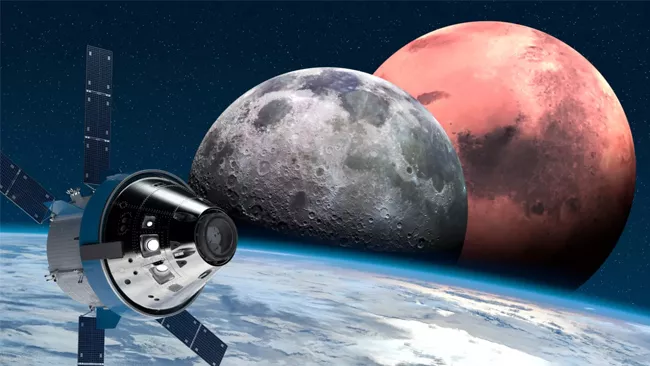

NASA Orion spacecraft

Orion is an integral part of NASA Artemis, which aims to return humans to the Moon and extend space exploration further.

TTEthernet® is at the core of this “nervous system,” allowing a mixed-criticality architecture. It enables the use of one single network for critical and non-critical data with three traffic classes: best-effort, rate-constrained, and time-triggered Ethernet, making it highly flexible and modular.

Mobile machinery

Hinowa - aerial machinery

Hinowa offers its customers mobile elevating work platforms with extensive equipment and great flexibility. Unified and consistent operational handling and maximum performance are key. For this project, TTControl implemented the full electro-hydraulic control of the machine, from track control to stabilization and aerial kinematics, together with Hinowa.

Rosenbauer - airfield stairs

Rosenbauer is one of the world's largest manufacturers of fire-service vehicles and firefighting equipment. One project involved an overhaul of the electronic architecture and the related software development process for airfield rescue stairs. The complexity of the system was reduced, and a virtual model was created for the hydraulic system to perform software tests remotely and develop the application software.

Industrial

Fill – smart factory solution

Fill is a leading international machine and plant engineering company. TTTECH Industrial’s IIoT platform Nerve supports Fill’s smart factory solution Cybernetics. The project required developing customer-specific, platform-independent dashboards for optimal overview and detailed analysis of production and machines.

Felss – Smart Services

Machine builder Felss worked with TTTECH Industrial when rolling out their Smart Services solution for tool wear detection. Nerve from TTTECH Industrial allows the recording and saving of all critical machine, production, process, and component data to enable real-time analysis, data filtering, and knowledge generation at the source, and reduces the volume of data transfer to IIoT platforms.

HOERBIGER - gas compressors

HOERBIGER provides performance-critical products and safety solutions They use TTTECH Industrial’s IIoT platform as the supporting infrastructure at the edge to provide data acquisition, processing, and visualization together with cybersecurity functions for their predictive maintenance solution for gas compressors.