After a duration of almost four years, the EU funded project to create a Space Ethernet Physical Layer Transceiver (SEPHY) was completed at the end of 2018. A prototype chip was developed and built by the project partners from industry and academia which can now be qualified for space applications, but also for use in other environments where harsh conditions like radiation place special requirements on communication devices.

As complexity increases in spacecraft and space systems, so do the requirements for data communication with ever increasing demand for bandwidth. Not only does safety-critical information have to be relayed, but equipment and components also need to be able to synchronize and connect with each other. Therefore, reliable, high-speed transmission of messages is a key technology need.

Several space agencies including the European Space Agency (ESA) as well as the National Aeronautics and Space Administration (NASA) have identified an open networking technology which almost perfectly addresses this need: Time-Triggered Ethernet (TTEthernet). This technology is based on Ethernet, which is already widely used in terrestrial applications (offices, industrial automation and increasingly also in cars) and for which international standards have been defined. These ensure the interoperability of communication devices, a feature of highest importance in complex systems made up of a variety of components from different vendors. TTEthernet is a deterministic version of Ethernet that robustly integrates highly critical real-time functions like flight controls and life-support systems with lower priority data on one single physical network while guaranteeing predictable system behavior.

The European space sector established the H2020-LEIT-Space-Competitiveness program to further non-dependence for the European Space Industry. SEPHY was one of the projects within this program. It ran for almost four years from May 2015 to December 2018. Funded by the European Commission (EC), its aim was to develop a radiation-hardened Ethernet physical layer (PHY) device in Europe. Called Space Ethernet Physical Layer Transceiver (SEPHY), it supports Ethernet networking technologies as defined by NASA and ESA. As the first of its kind manufactured in Europe, it will not be subject to US export restrictions, providing an important benefit for European companies in a highly competitive and rapidly changing market environment. Another critical point in developing the transceiver was that it needs to withstand the rugged space environment and the high radiation levels found there.

Six well-known industrial and academic partners from Europe came together in the SEPHY project to jointly develop the chip. Each partner had clear responsibilities:

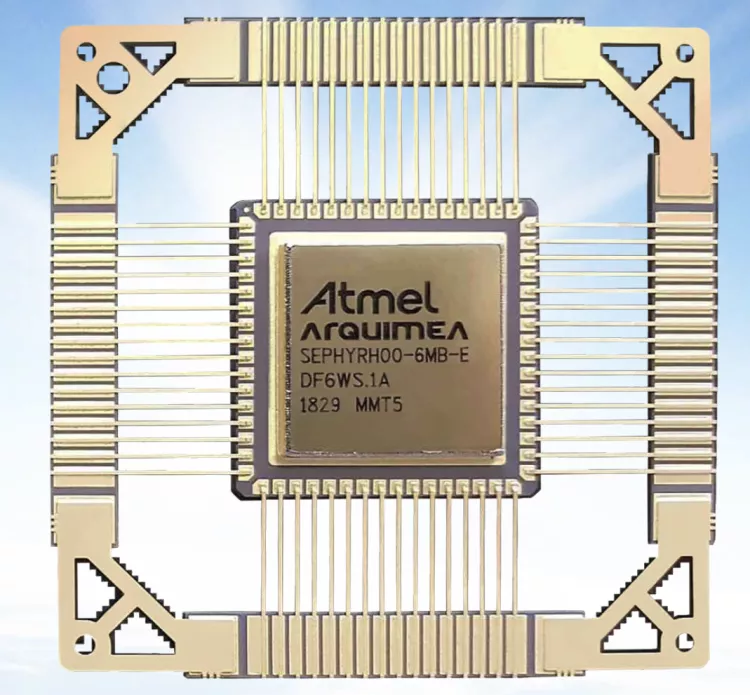

Arquimea Ingeniería S.L.U., Spain, served as project coordinator and took care of system design and verification as well as analogue design and verification. IHP GmbH, Germany, realized the digital design and Thales Alenia Space España, S.A. was responsible for functional testing and the irradiation campaign. Manufacturing and assembly of the prototype chips were carried out by Microchip Technology Nantes, France. TTTech Computertechnik AG, Austria, worked on the definition of requirements, the network level testing and standardization, as well as taking over dissemination and communication of the project. The roadmap and standardization activities were conducted by the Universidad Antonio de Nebrija (Universitas Nebrissensis S.A.), Spain.

The SEPHY chip developed in the project is an extremely robust, highly reliable transceiver for 10BASE-T and 100BASE-TX Ethernet using category 5 unshielded twisted-pair cabling. It features enhanced ESD protection and supports MII and RMII for maximum flexibility in MPU selection. For high-volume programs is it already available in an affordable, compact 64-pin PQFP package, otherwise it comes in a space-grade ceramic package. The chip was developed in a radiation-hardened, 150 nm mixed signal silicone-on-insulator (SOI) process to ensure reliability in the harshest radiation environments.

The SEPHY prototypes achieved excellent results in both the radiation and the network level tests and are now ready to be qualified.

- For further commercial information please contact ARQUIMEA INGENIERIA S.L.U. at info@arquimea.com.

- Find out more about the SEPHY chip in the flyer.

- Visit the SEPHY website: www.sephy.eu

- Watch the final project video: